501-T

A portable single lance net weight filler for top-surface filling of non-foaming liquids.

Description

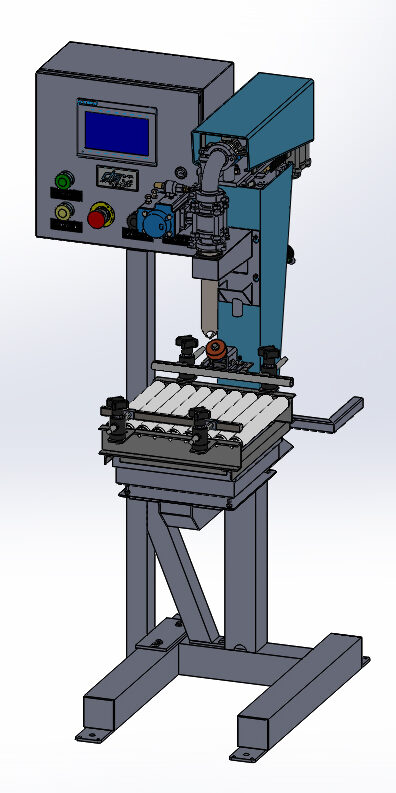

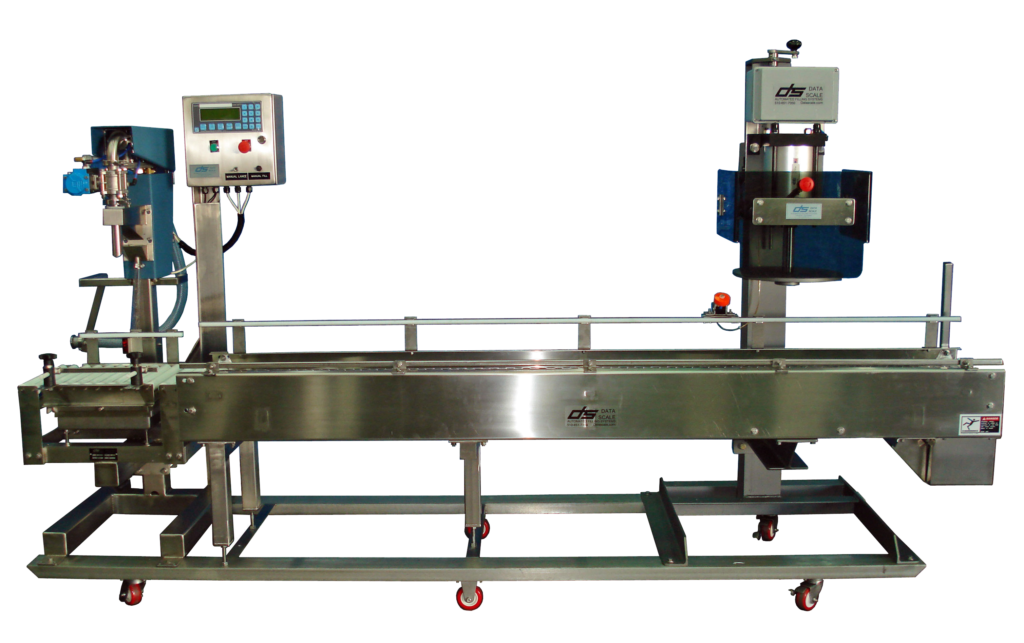

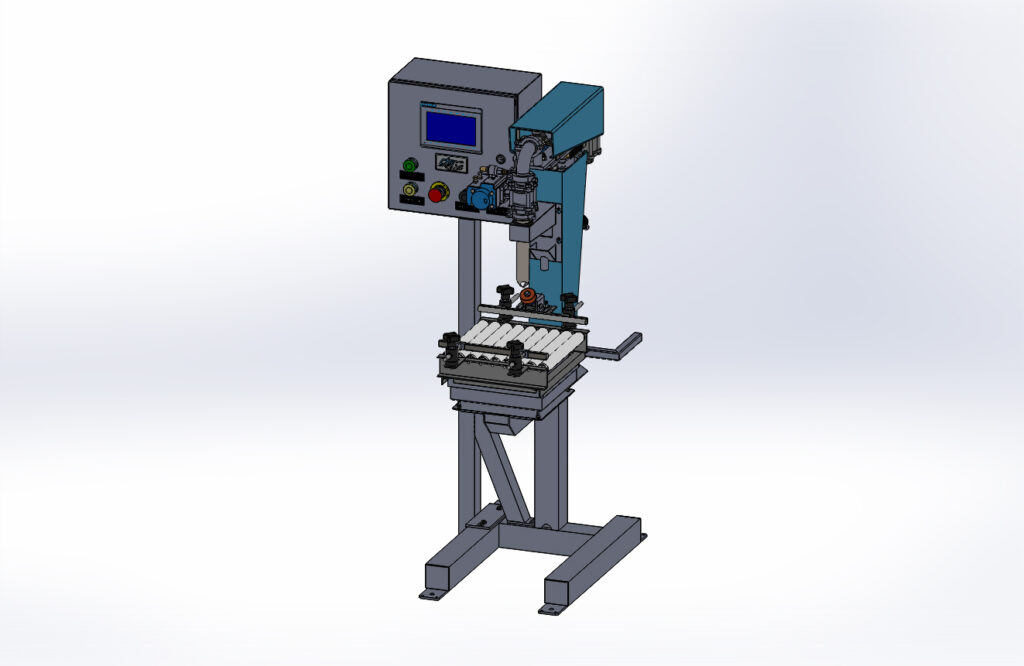

MODEL 501-T AUTOMATIC PAIL FILLER

Single lance, automatic net weight, TOP-surface filler, for non-foaming liquid. 2–6-gallon containers. 3-6 cpm. Accuracy 0.01#. Completely assembled and fill tested at the factory.

Data Scale electro/pneumatic weight controller; 100# X 0.01#

-

Featuring Allen-Bradley Micro 850 PLC.

-

Panel View seven-inch touch screen.

-

Start & E-Stop buttons.

-

Operator prompting, fill status, pause, abort.

-

NEMA XII control enclosure 16″X16″, 115 VAC 3 AMP.

-

Manual buttons for lance control, fill top off, sample, and flush

Automatic net weight filling program with: Touch Screen

-

Automatic Learn: fill accuracy Pre-ac adjust.

-

Fill Pause and Resume mode.

-

3 speed filling program: slow/fast/dribble, Touch screen settable.

-

Auto tare with motion sensing.

-

Auto fill accuracy adjust.

-

No fill fail-safe for lance misalignment.

-

No fill fail-safe for lance down.

-

Ascending lance during fill, programmable weight based.

-

Lance position sensors & special program.

-

Fail safe prevents lance from coming out of pail during filling.

-

Serial & Ethernet & Input/output CAPABLE.

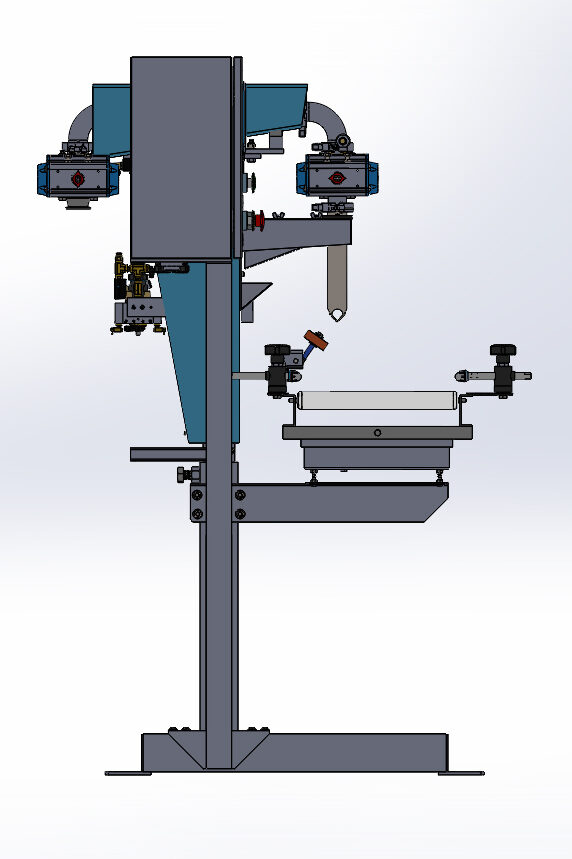

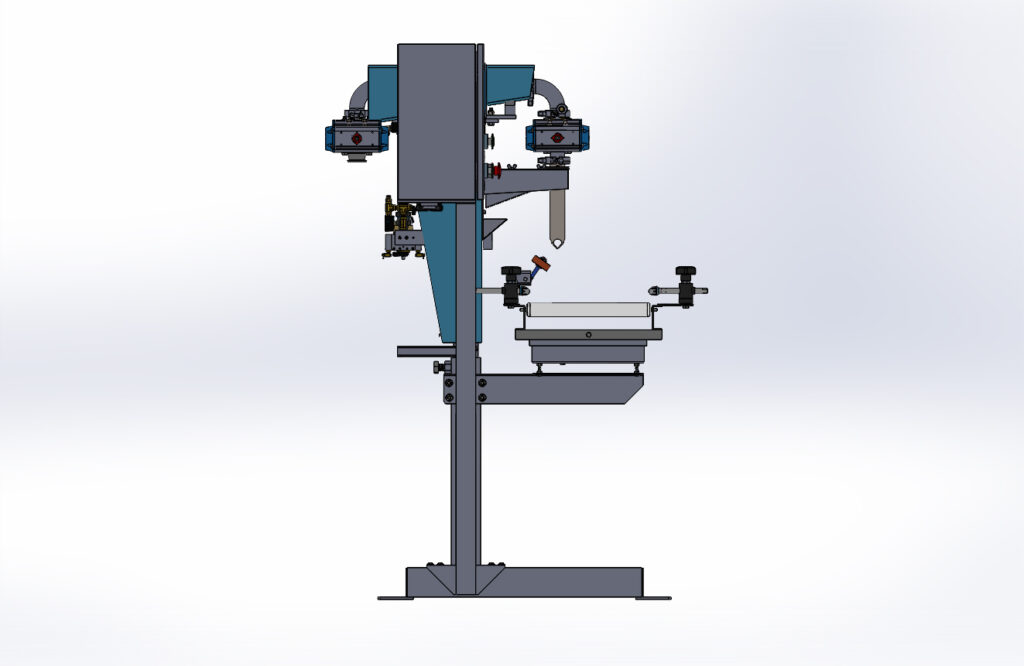

TOP-Surface Fill Head: Manifold Lift Mechanism:

-

Heavy wall welded square Tube steel frame.

-

Quick adjustment for: containers size and height.

-

Lower arm assembly, Stainless Steel.

-

Automatic Drip Catcher, Stainless Steel.

-

Lance wiper/guide,

-

316 SS TOP-surface, lance/manifold assembly.

-

Full Port ball valves, with Teflon seat & air/air actuators.

-

Spring close fail-safe for product fill valve.

-

No fill fail safe sensors for lance misalignment.

-

No fill fail safe sensors for lance down.

-

1.5″ product inlet, with 1.25″ final valve, lance.

-

Braided vinyl connector hose with swivel support.

-

Adjustable-rate dribble control.

-

Filter regulator for supply air: 100 PSI @ 10 CFM.

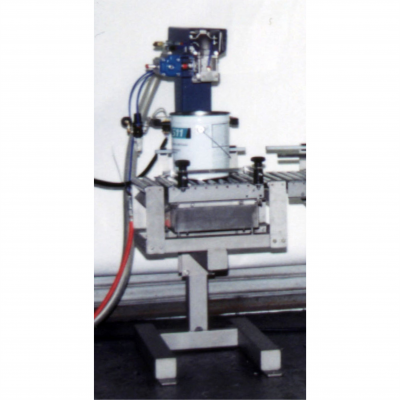

Scale 12″ x 12″, 100# capacity, 100% overload. NTEP class III. Includes galvanized roller conveyor on scale.

Gallery