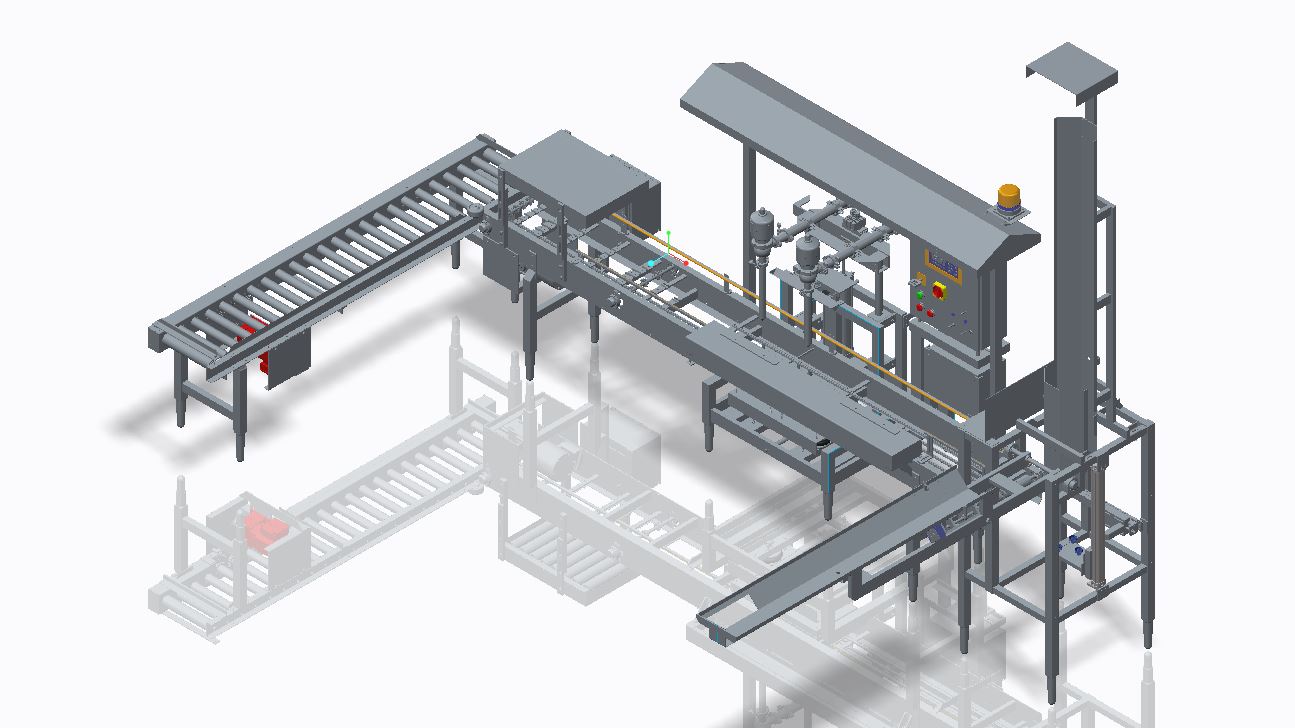

502-IL

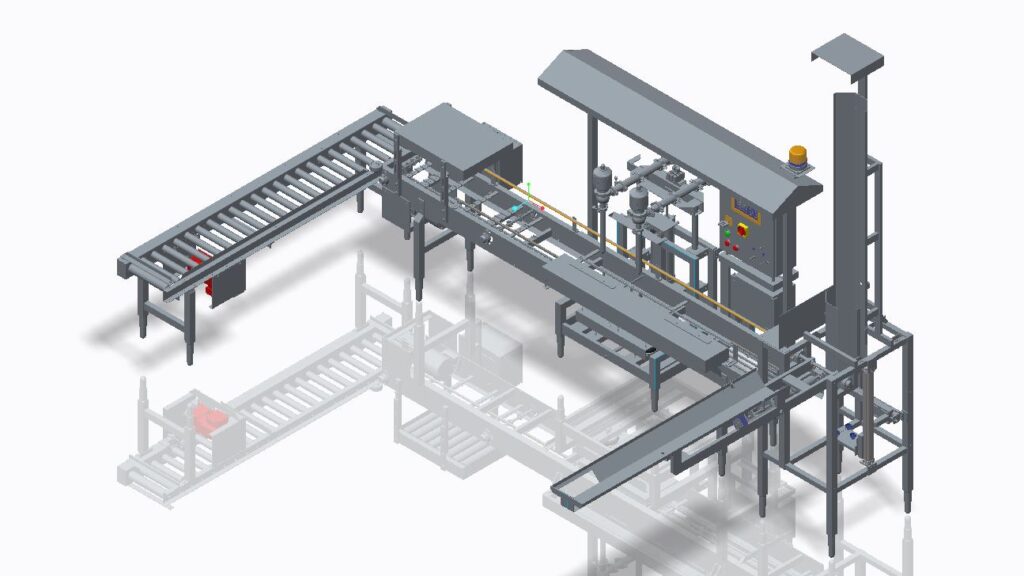

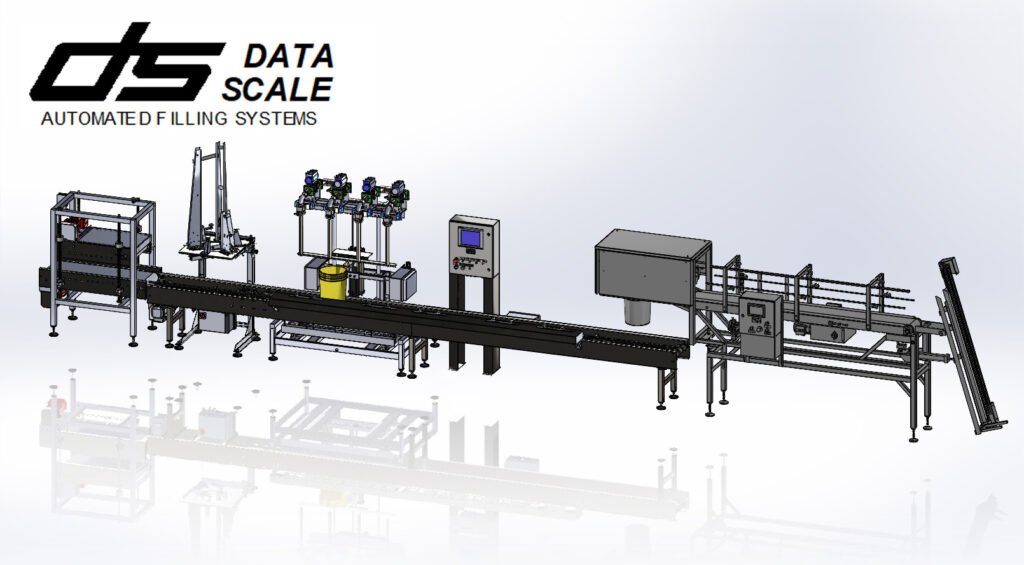

Dual head in-line automated net-weight filler with continuous flow for filling of a variety of liquids.

Description

MODEL 502-IL: 2-HEAD, DUAL LANCE, IN-LINE, AUTOMATIC NET WEIGHT FILLER:

FOR: 2-6 GALLON PAILS TOP OR SUB SURFACE, AVAILABLE FOR BOXES, JUGS, & OPEN OR CLOSED HEAD CONTAINERS, MEDIUM VISCOSITY or FOAMING LIQUIDS UP TO 14/MIN. @ 0.02# ACCURACY

Data Scale electro/pneumatic weight CONTROL SYSTEM;

-

Featuring Allen-Bradley Micro 850 PLC.

-

Panel View 10”-inch touch screen.

-

Fill, Start & E-Stop buttons.

-

Operator prompting, fill status, pause, abort.

-

NEMA XII 20″X 24″ control enclosure, 115 VAC 3 AMP.

-

Manual buttons for lance control, fill top off, sample, and flush.

Automatic net weight filling program with: Touch Screen

-

Automatic Learn: fill accuracy Pre-ac adjust.

-

Fill Pause and Resume mode.

-

3 speed filling programs: slow/fast/dribble, Touch screen settable.

-

Auto tare with motion sensing.

-

Auto fill accuracy adjust.

-

No fill fail-safe for lance misalignment.

-

No fill fail-safe for lance down.

-

Ascending lance during fill, programmable weight based.

-

Lance position sensors & special program.

-

Fail safe prevents lance from coming out of pail during filling.

-

Automatic “Sleep Mode” timer.

-

Automatic drip tray retraction, time out.

-

Serial & Ethernet & Input/output CAPABLE.

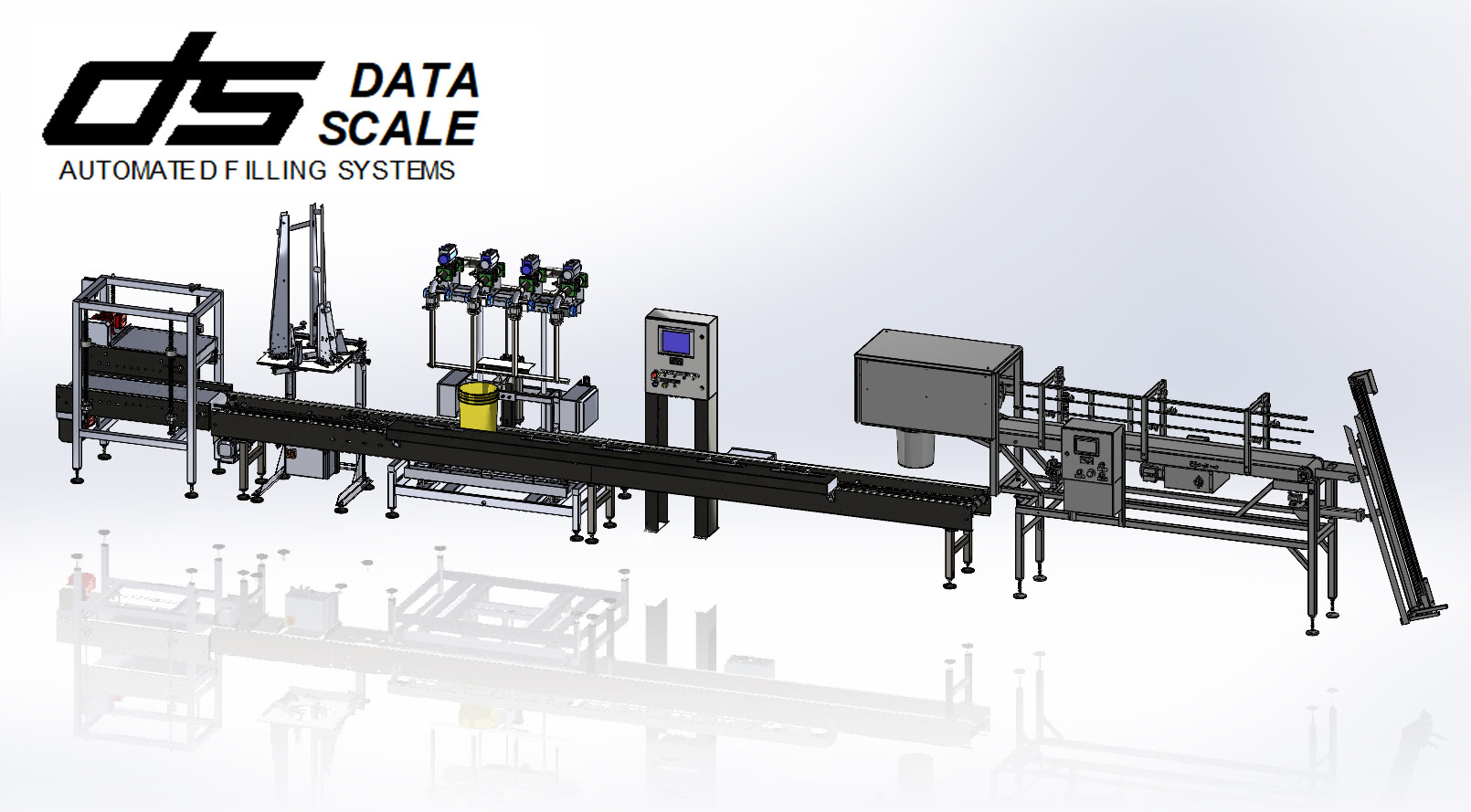

Roll Through Lid Press – Lid Placer -504 IL – De Nester

Fully Automated System For all Types of Products and Containers

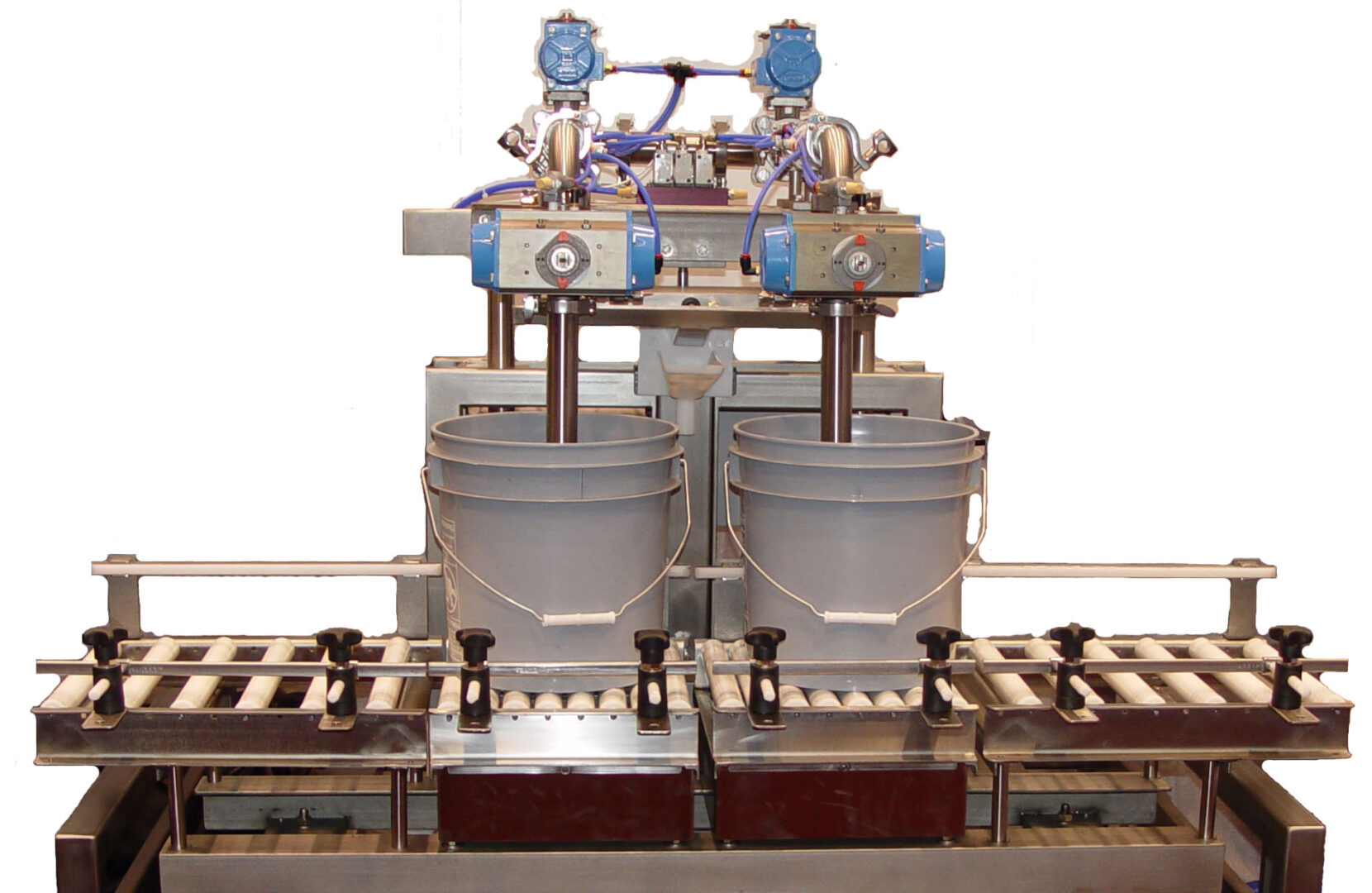

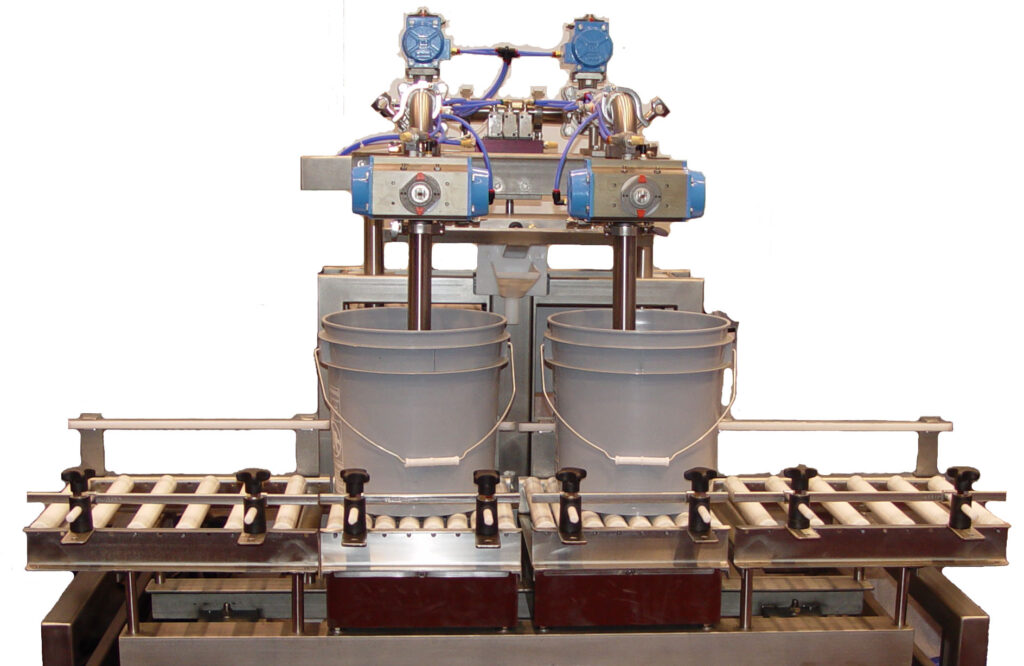

TWO Head: Manifold Lift Mechanism:

-

One-piece, Heavy wall welded rectangular tube steel frame.

-

Quick adjustment for: containers, spout, height & diameter.

-

Stainless Steel automatic drip catcher.

-

Laser Sensors for lance stroke position & misalignment.

-

316 SS Top or SUB-surface, Dual lance/manifold assembly:

-

Full Port ball valves, with Teflon seat & air/air actuators.

-

Spring close fail-safe for product fill valve.

-

2″ product inlet, with 1.25″ final valves.

-

Adjustable-rate dribble.

-

Filter/regulator. 100 PSI@ 10 CFM

TOTAL AUTOMATIC CONTAINER INDEXING SYSTEM: Including:

-

Allen Bradley PLC specially programmed in NEMA XII enclosure.

-

In-feed indexing mechanism to separate container.

-

Adjustable Pin stops for round 2.5 – 5 Gallon Containers

-

Sensors at each container position for “no pail/no fill” failsafe.

-

Pop-up scale/grid mechanism installed on filler frame.

-

Automatic conveying & indexing through Staging, Filling & Exit.

-

IN-LINE FILLER, INDEX CONVEYOR, 15′ long:

-

Motor control in NEMA XII enclosure.

-

pop up scale grids & pin stop rail.

-

Continuous double pitch chain with UHMW guides.

-

Gear motor 3/4 HP, 230 VAC 3 Ph. TEFC.

Gallery